R&D Themes

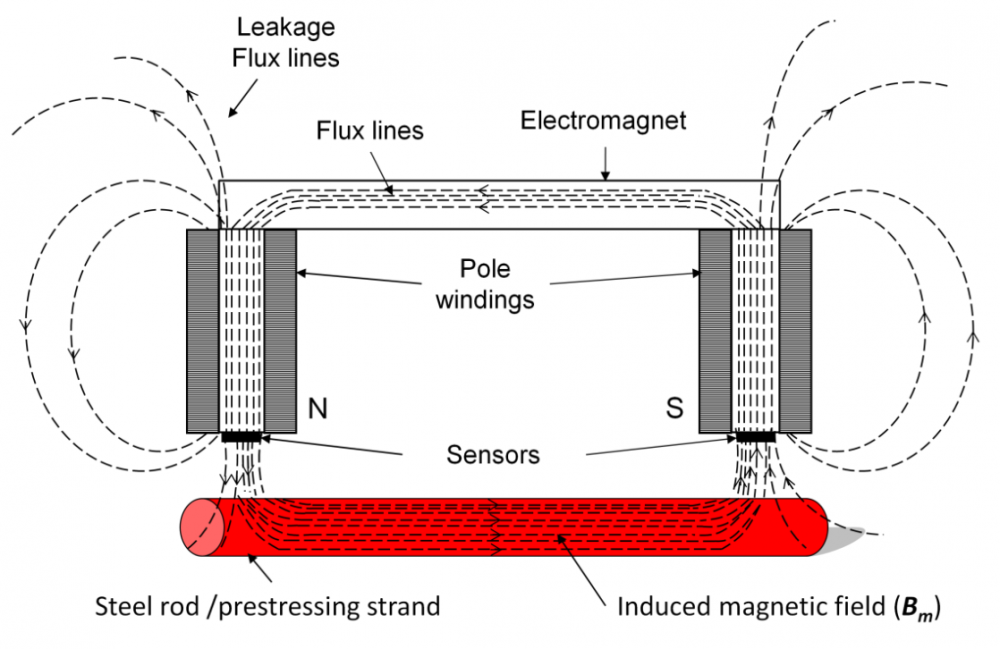

Electromagnetic Methods for Non Destructive Analysis of Fe-C Steels

CMPhy is developing innovative measurement methods allowing the characterization of steel by magnetic and electrical methods (eddy currents) in order to evaluate structural properties such as the metallurgical phases involved, the state of mechanical stress, grain deformation.

Development of methods for non-destructive analysis as early as possible in the parts manufacturing cycle, analysis on hot structures and in a restrictive, highly hostile environment

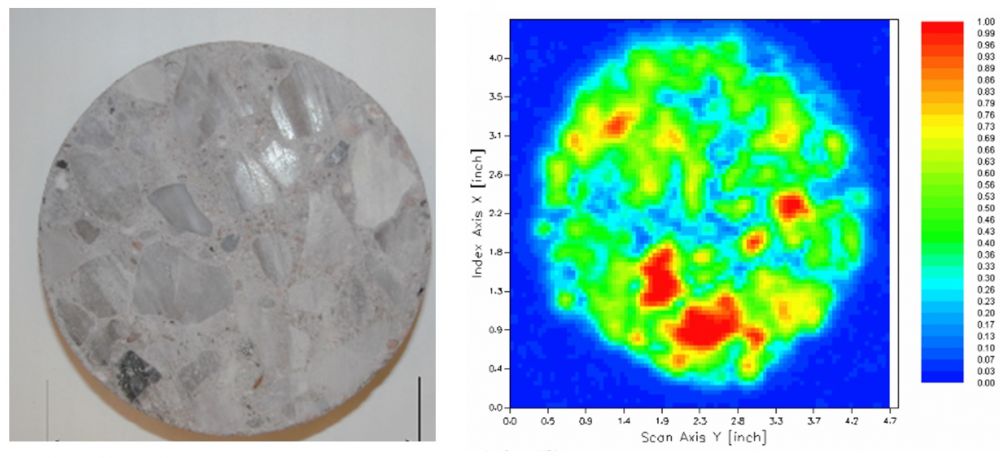

Non Destructive Analysis by Ultrasonic and Vibratory Methods

Development of ultrasonic methods (temporal and spectral analysis) for mapping mechanical moduli (Young's modulus, shear), evaluation of the size and orientation of grains on Fe-C steel in particular, use of methods with or without contact.

==> Methods complementary to classical mechanical / metallurgical / metallographic analysis

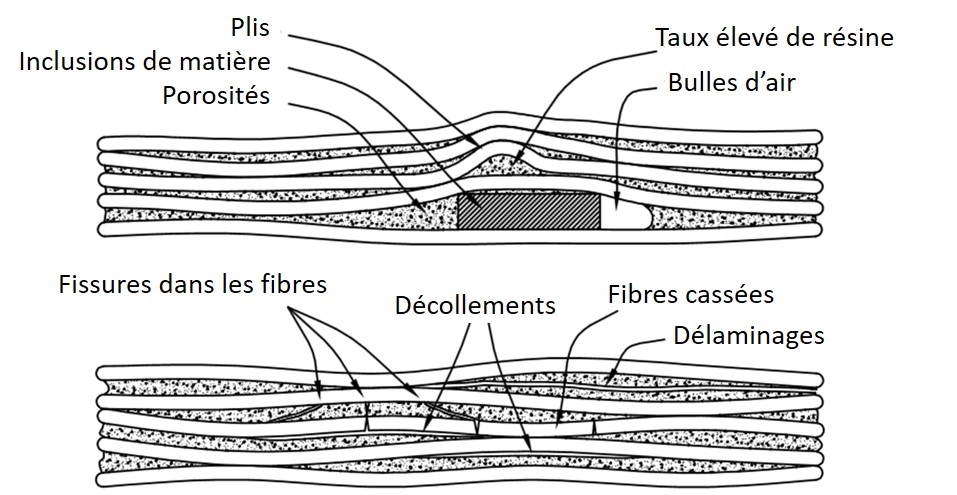

Non Destructive Testing of Carbon Composites

Development of methods for detecting defects such as cracking, fiber breakage, delamination, air bubbles, inclusion of material. Analysis of structure, orientation, fiber compaction, density, homogeneity. Study and production of Ultrasonic and Eddy Current equipment for the analysis and control of these materials.

==> Detection possible on other types of composites: glass, silica, metal matrix, ceramic

Miniaturization of Non Destructive Control Sensors

CMPhy develops and integrates miniaturized Non Destructive Testing sensors for Ultrasonic, Guided Waves, Eddy Currents and Magnetic Measurements applications. Wide possibility in terms of range of measures and targeted applications: monitoring of structures, monitoring of critical areas, evolution of faults.

Integration of permanent sensors in order to carry out material health monitoring and analysis of fine structures: evaluation of defects and also of the structural properties of the materials