Magnetic particle inspection systems with Very Low Frequency (VLF) magnetic field

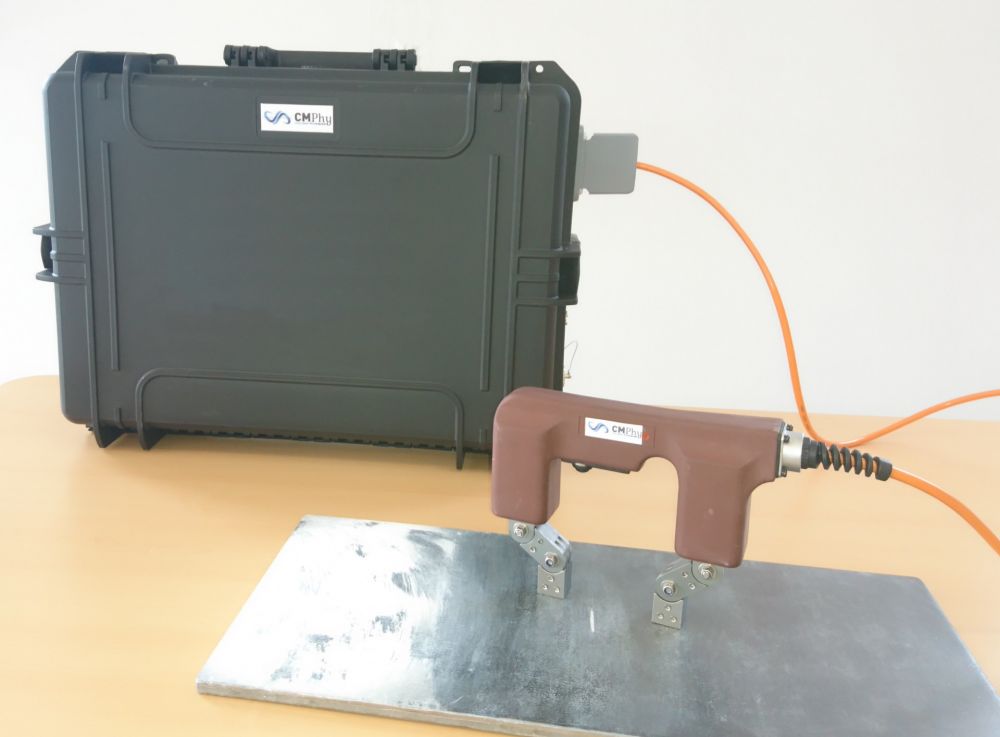

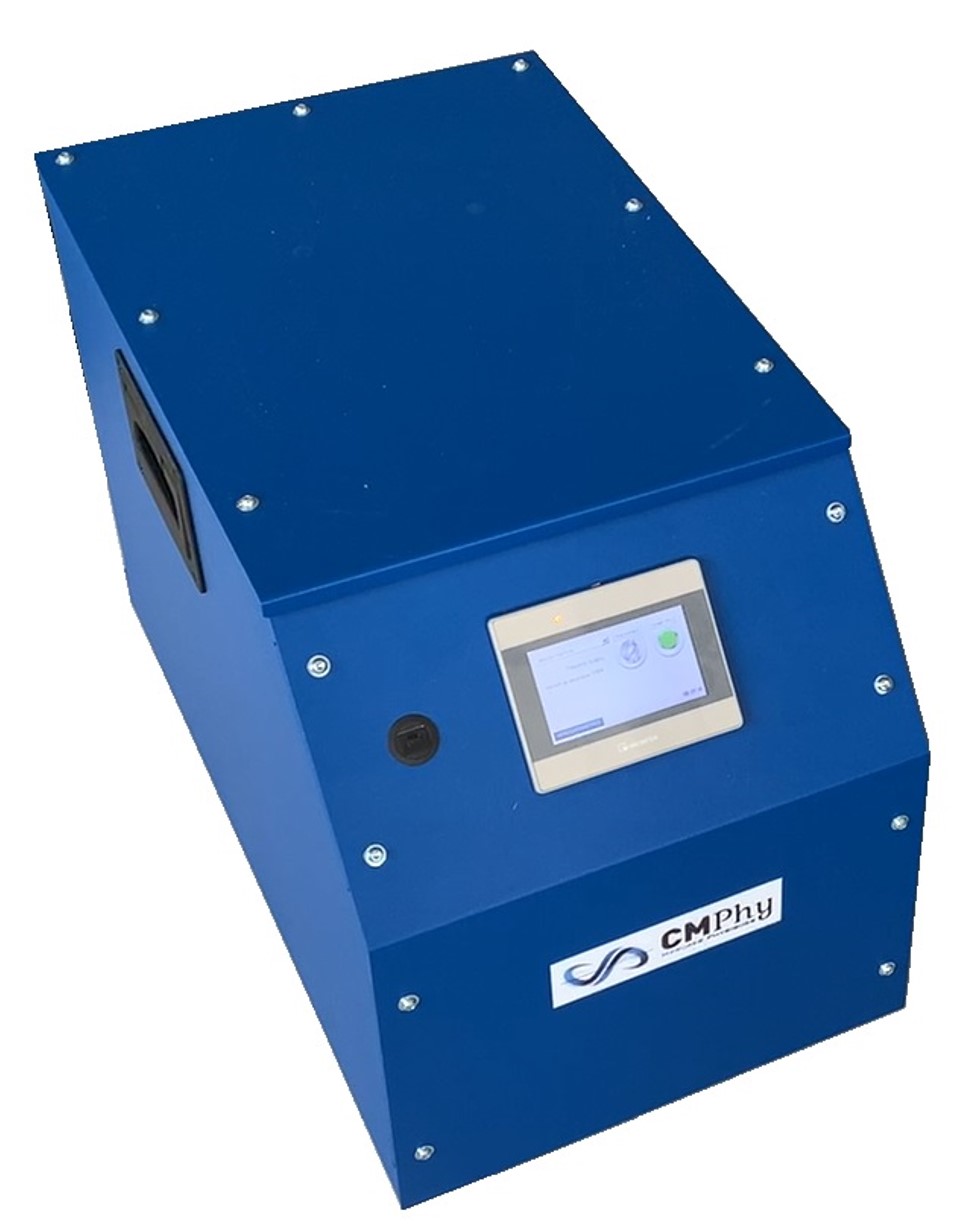

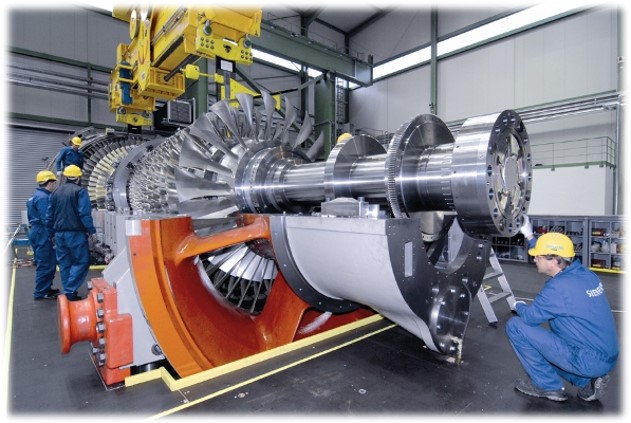

Wide range of equipment available: electromagnet, portable generator, test bench, rotating magnetic field system (tank, head for localized magnetization)

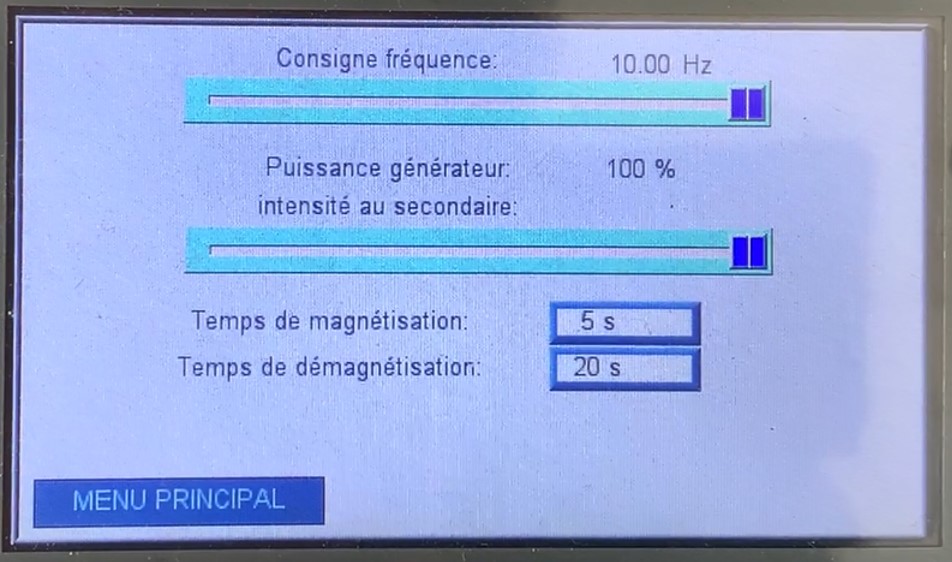

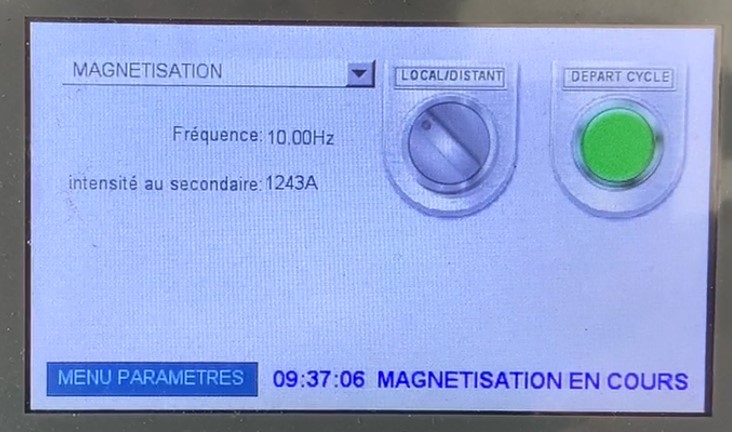

By Very Low Frequency Magnetoscopy we mean the use of magnetic fields with a frequency <10 Hz. This technology offers significant gains compared to traditional systems working at a frequency of 50 Hz:

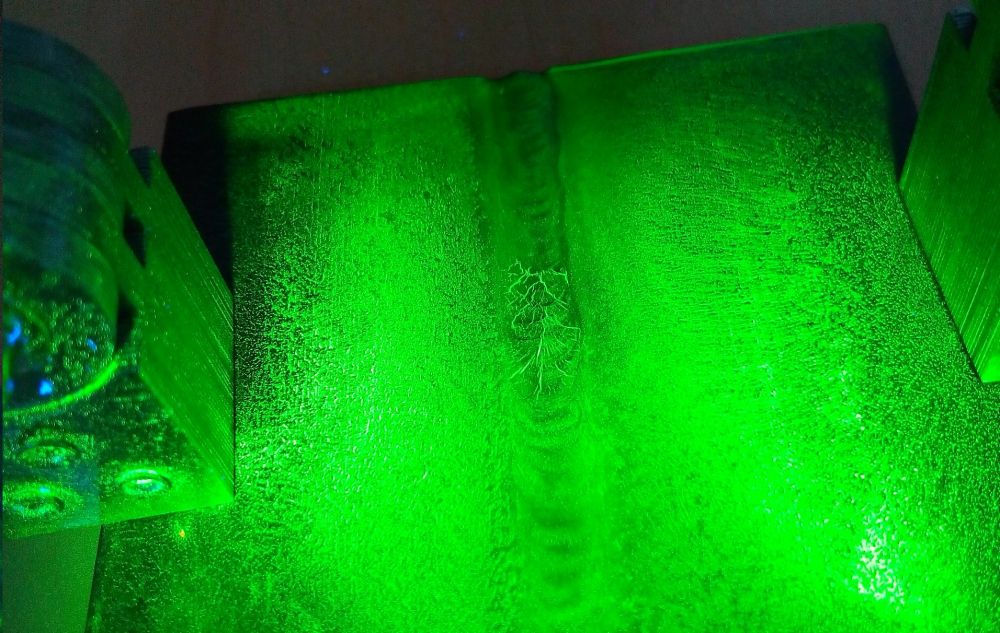

Decrease power consumption by about a factor of 5 by decreasing the output voltage required to power the magnetization circuits. Better detection of deep defects, by reducing the skin effect. Defects are detectable up to 3mm deep (depending on their size and morphology).

In terms of operator safety in terms of exposure to magnetic fields, the use of very low frequencies allows full compliance with the requirements described in European Directive 2013/35 / EU.

Control of painted parts, the use of a very low frequency magnetic field (TBF), due to the generation of a magnetic flux interacting with the entire depth extension of the defect, makes it possible to significantly increase the quantity of magnetic particles retained on the surface and thus allows magnetic particle inspection of painted parts (e ~ 100 to 500 μm depending on the type of paint). Therefore the probability of detecting the fault is significantly increased.

Demagnetization in depth, the use of very low frequency makes it possible to demagnetize very thick parts (> 20mm). Indeed, for frequencies between 2 and 10 Hz, the penetration depth of the lines of magnetic fields is greater than 10mm.